I. Changes in Market Demand

1. Booming Building Decoration Sector

With the diversification of modern architectural styles and the increasing aesthetic demands for building exteriors, colored anodized aluminum tubes are becoming more widely used in architectural decoration. They are particularly favored for applications such as building facades, railings, and handrails. In high-end commercial buildings, office towers, and luxury residential projects, the rich color options, excellent weather resistance, and metallic texture of colored anodized aluminum tubes add unique visual effects and a modern touch. As a result, the demand for these tubes in the construction industry is growing steadily, with higher requirements for product specifications, customized colors, and surface treatment processes.

2. Emerging Industrial Manufacturing Needs

Colored anodized aluminum tubes are also finding new applications in industrial manufacturing. In the electronics industry, their good thermal conductivity and electrical insulation, combined with an appealing appearance, make them suitable for heat dissipation components and decorative shells of electronic products. In the automotive and aerospace sectors, the lightweight, high strength, and corrosion resistance of these tubes are being explored for specific parts, such as engine cooling tubes in automobiles and internal structural components in aerospace vehicles. Although the current application scope is limited, the potential market demand is significant and could grow rapidly with further technological breakthroughs.

II. Technological Innovation and R&D Progress

1. Continuous Optimization of Production Processes

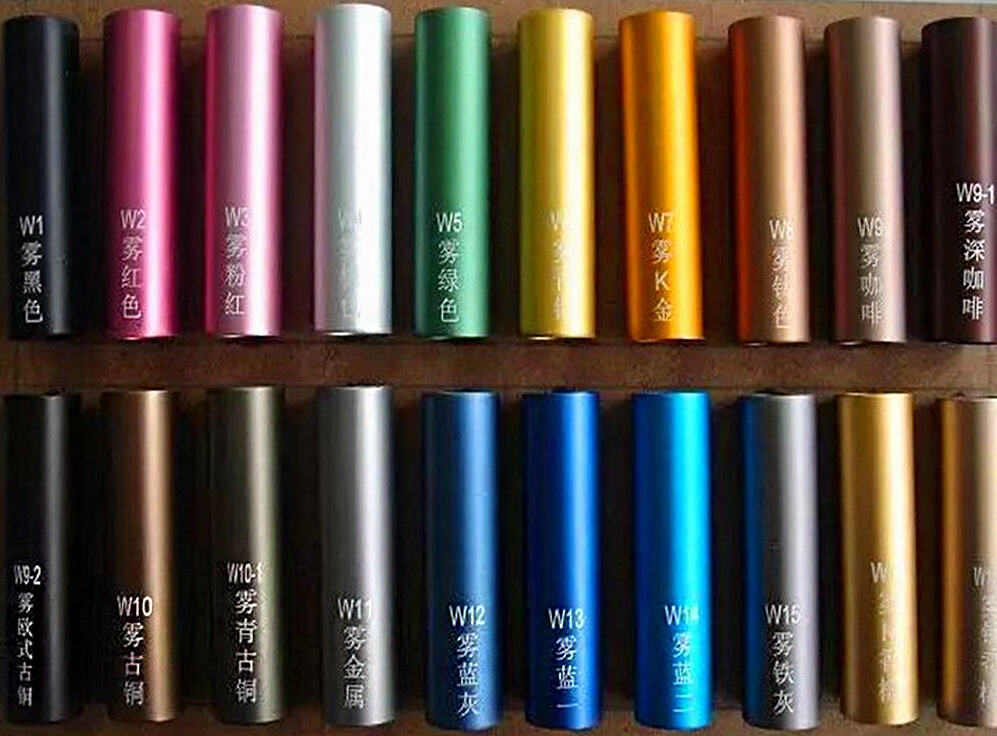

To improve the quality and production efficiency of colored anodized aluminum tubes while reducing costs, companies are increasing R&D investment in production processes. For instance, improvements in anodizing processes allow precise control of parameters like electrolyte concentration, temperature, current density, and oxidation time. This enables better regulation of the oxide layer's thickness, hardness, and porosity, enhancing the wear resistance, corrosion resistance, and color adhesion of the aluminum tubes. Additionally, advancements in dyeing techniques, such as micro-arc oxidation dyeing and laser-induced dyeing, have expanded the color range and achieved more vibrant, durable, and uniform colors.

2. Improvement and Expansion of Material Properties

Beyond traditional performance advantages, researchers are developing colored anodized aluminum tubes with special properties to meet high-end application needs. For example, adding trace elements or using special heat treatment processes can endow the tubes with better high-temperature resistance, fatigue resistance, and electromagnetic shielding capabilities. Moreover, for potential applications in the biomedical field, colored anodized aluminum tubes with biocompatibility and antibacterial properties are being developed. Although these specialized tubes have not yet been commercialized on a large scale, they represent an important direction for future technological development and could open up new market growth opportunities.

III. Environmental and Sustainable Development Trends

1. Widespread Adoption of Green Production Processes

As global environmental awareness strengthens and environmental regulations become stricter, the colored anodized aluminum tube industry is under increasing pressure to be more eco-friendly. Companies are thus investing more in green production technologies. For example, replacing traditional chromium-containing passivation processes with chromium-free ones reduces heavy metal pollution. Optimizing energy management with energy-efficient equipment and technologies also lowers energy consumption during production. Additionally, improved treatment and recycling of wastewater, exhaust gases, and waste residues contribute to cleaner production and efficient resource utilization. These efforts not only reduce environmental risks but also enhance the industry's sustainable development capabilities.

2. Sustainable Product Design and Recycling

In addition to green production, sustainable product design and recycling are becoming key trends. During the design phase, companies focus on selecting materials and optimizing product structures to increase the lifespan and recyclability of colored anodized aluminum tubes. For example, using biodegradable packaging materials reduces waste, and designing products for easy disassembly and recycling ensures that the tubes can be effectively recycled at the end of their life. Although recycling technology for colored anodized aluminum tubes is still in its infancy, it has garnered significant attention from industry players and research institutions. Initial recycling solutions are already being piloted, with the potential for wider adoption in the future to support the industry's sustainable growth.

Conclusion The colored anodized aluminum tube industry is currently at a critical juncture with both opportunities and challenges ahead. With the growing market demand and ongoing technological innovation, the industry is poised for broader development prospects. However, companies must also confront intense market competition, environmental pressures, and the need for technological upgrades. Only those that can keenly grasp market dynamics, increase R&D investment, promote green and sustainable development, and implement differentiated competition strategies will stand out and achieve long-term stable growth in the future.