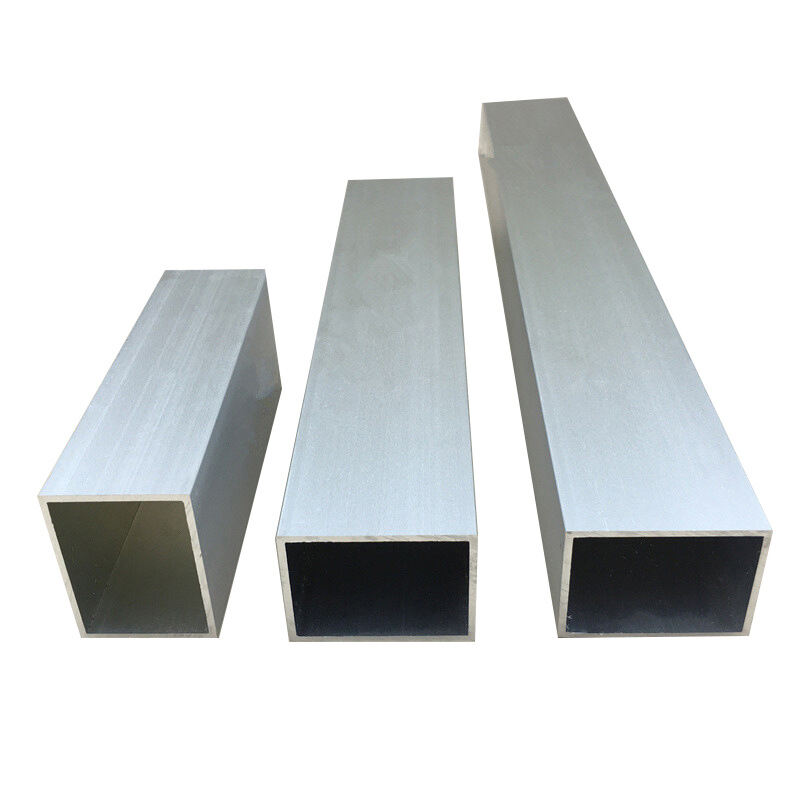

Aluminum Tube

Aluminum Tube is a lightweight and high-strength metal tubing, widely used in construction, aerospace, automotive, and marine industries due to its excellent corrosion resistance and processability.

- Overview

- Parameter

- Recommended Products

Aluminum Tubes are categorized into several series based on alloy composition and application, including Series 1000 (pure aluminum), Series 2000 (aluminum-copper alloy), Series 3000 (aluminum-manganese alloy), Series 5000 (aluminum-magnesium alloy), Series 6000 (aluminum-magnesium-silicon alloy), and Series 7000 (aluminum-zinc alloy). Different series of aluminum tubes have distinct properties. For example:

2024 Aluminum Tube has high strength and good fatigue resistance, making it suitable for aerospace applications.

5052 Aluminum Tube has excellent corrosion resistance, especially in marine and chemical industries.

6061 Aluminum Tube is known for its good weldability and corrosion resistance, commonly used in industrial piping and construction.

Aluminum tubes are produced through extrusion and drawing processes, available in various types such as seamless tubes, thin-walled tubes, and finned tubes. Additionally, aluminum tubes can be surface-treated with anodizing, painting, and polishing

Parameter

|

Material |

Aluminum Alloy (e.g., 1060, 3003, 5052, 6061, 7075) |

|

Shape |

Round, Square, Rectangular, Finned, etc. |

|

Size range |

Outer Diameter: 5 mm~1320 mm; Wall Thickness: 0.5 mm~200 mm; Length: customizable |

|

Characteristics |

Lightweight, high strength, corrosion-resistant, good electrical and thermal conductivity |

|

Surface treatment |

Anodizing, painting, polishing, galvanizing, etc. |

|

Application |

Construction, aerospace, automotive, marine, industrial piping, decoration, etc. |

The above information summarizes the common characteristics and application areas of aluminum tubes. Specific parameters and applications can be customized according to customer needs and industry standards.